The PHA-Binder project (full name: Tuneable PHA-Based Biodegradable Binder Platform project), part of the Interreg-funded EMPHATI initiative, recently received funding to advance eco-friendly innovations in the coatings industry. This one-year project aims to develop sustainable polyhydroxyalkanoate (PHA)-based binders that are free from microplastics, moving the paint industry closer to environmentally responsible solutions.

Prof. Dr. Mark Rüsch gen. Klaas of the Hochschule Emden-Leer, one of the project’s lead researchers, emphasizes that while this initial phase may not yield a market-ready product, it’s set to establish a clear commercialization path. “We aim to reach a proof of concept and outline a path to a viable product,” says Rüsch.

Key goals

The project centers on polyhydroxyalkanoyates (PHA) derivatives—biopolymers produced through fermentation—that hold promise as cost-effective, sustainable alternatives for the paint industry. “PHAs are used in sectors like medicine, but the scale is limited and costs are high,” explains Prof. Dr. Mark Rüsch. “However, they may be ideal for paints, where cost and sustainability can balance well.”

A key goal is to replace petrochemical-based binders, which release microplastics, with bio-based binders that degrade naturally. “We aim to create a paint that remains stable while in use, yet safely degrades over time—a difficult but essential balance for sustainability,” Rüsch says.

Collaboration and Cross-Border Partnership

The project brings together three core partners: Hochschule Emden-Leer, Hanze University of Applied Sciences in Groningen, and the company Wydo NBD, both based on Campus Groningen. The Hochschule Emden-Leer, led by Rüsch, handles polymer modification and analytics.

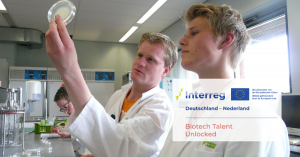

The Hanze University, under Janneke Krooneman, Professor bioconversion & fermentation technology, leads on microbiological research focussing on fermentative PHA-production. Krooneman explains, “We aim to use natural fermentation to produce PHAs that require minimal modification, making the process more efficient and sustainable. This is key to developing a truly bio-based binder for coatings.”

Wydo NBD, led by Ron Hulst, focuses on testing the binders in practical applications across various coating environments. Hulst adds, “Since Wydo’s founding in 2016, we’ve aimed to bridge the gap between research and market-ready products, making eco-friendly solutions accessible to both the paint and broader manufacturing sectors.”

Streamlining production chains

The vision behind the PHA-Biobinder project is to streamline production chains, enhancing both efficiency and sustainability. Rüsch explains, “After years of experience in biomass-based products, I see the importance of shortening the pathway from raw material to final product. This project fits perfectly within that vision.”

If successful, the partners hope to continue developing bio-based paint solutions, ultimately aiming to bring a viable, sustainable alternative to traditional paints to market.

About EMPHATI

EMPHATI stands for Ecofriendly Materials from PHA Tuned for Injection Moulding. In the EMPHATI project, made possible by an Interreg grant, Dutch and German companies and research institutions are collaborating on the development of new sustainable and environmentally friendly products based on PHA (polyhydroxyalkanoates). PHAs are natural plastics that are biodegradable, making them a promising and sustainable alternative to fossil-based plastics. As a partner, the BIO Cooperative bridges the gap to the broader plastics processing industry in North Netherlands and offers funding opportunities for innovators in PHA’s.

The project partners in the EMPHATI project are: 3N Kompetenzzentrum e.V., Ecoras, bekuplast GmbH, TKT Kunststoff-Technik GmbH, H&P Moulding Emmen B.V., IST Ficotex e.K., Hochschule Bremen, NHL Stenden, BINDER 3D B.V., Avans Hogeschool, Hanzehogeschool Groningen, and Netzwerk Oberfläche NRW e.V. Read more on EMPHATI on our site and at Interreg.

Photo credits: Gert Hofstede, Kemal Koç, and Noëlle ten Boer at the Hanze fermentation lab for Renewable Molecules (FERMO Lab). The photographer is Ward Jonkman